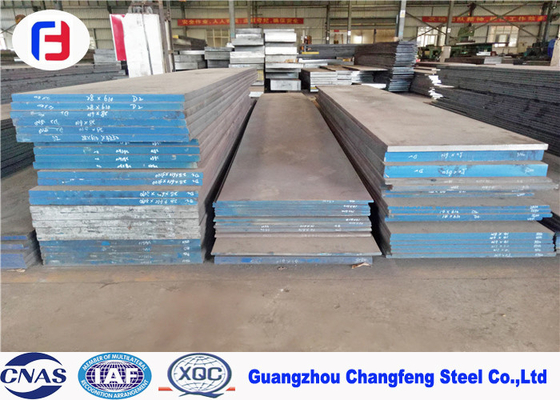

Special Quenched and Tempered Tool Steel Flat Bar SAE5140 / 40Cr

SAE5140 / 40Cr steel is one of the most widely used steel in machinery manufacturing, it is suitable for making medium-sized plastic mold.

Chemical composition(%):

| C |

Si |

Mn |

S |

P |

Cr |

Ni |

Cu |

| 0.37-0.44 |

0.17-0.37 |

0.50-0.80 |

≤0.035 |

≤0.035 |

0.80-1.10 |

≤0.30 |

≤0.30 |

Applications:

1. The steel is used to manufacture mechanical parts with moderate load and moderate speed, such as steering knuckle and rear axle of the car, gear, shaft, worm, spline shaft and top cover on the machine tool.

2. After quenching and tempering at medium temperature for the manufacture of high load, impact and moderate speed work of the parts, such as gears, spindles, pump rotor, slider, rings, etc .;

3. After quenching and tempering at low temperature for the manufacture of heavy load, low impact and wear resistance, the cross section of the physical thickness of 25mm below the parts, such as worm, spindle, shaft,

4. After quenched and tempered and high frequency surface hardening for the manufacture of high surface hardness and wear resistance without great impact on the parts, such as gears, bushings, shafts, spindles, crankshafts, spindles, pins, connecting rods, Screws, nuts, intake valves and so on.

5. In addition, this steel is suitable for the production of various transmission parts for carbonitriding, such as gears and shafts with large diameters and low temperature toughness.

Availability and hardness

Annealed, hardness ≤ 207HBS.

Delivery condition:

Hot rolled or forged/ peeled or black surface/annealed or Q+T.

Delivery time:

For abundant stock, 15-20 days.

For customized products, 30-50 days.

More about SAE5140 / 40Cr tool steel

It is widely used in machinery manufacturing, the mechanical properties of this steel is very good.

But this is a medium carbon steel, quenching performance is not good, 40Cr can be hardened to HRC42 ~ 46. So if you need surface hardness, but also hope to play 40Cr superior mechanical properties, often 40Cr surface carburizing and quenching, so you can get the required surface hardness.

40Cr Elastic modulus E (20 ℃) / MPa 200000 ~ 211700, Shear modulus G (20 ℃) 80800

Welding process points:

1, Usually in the annealed (normalizing) state welding.

2, Welding methods are not limited

3, With a larger line of energy, appropriate to improve the preheating temperature, the general preheating temperature and the interlayer temperature can be controlled between 250 ~ 300 ℃.

4, Welding materials should ensure that the deposited metal composition and base metal is basically the same, such as J107-Cr

5, After quenching and tempering heat treatment should be promptly carried out. If the timely quenching and tempering difficulties, can be intermediate annealing or at higher than the preheating temperature for a period of time to exclude the proliferation of hydrogen and soften the organization. For the complex structure, the weld more products, welding a certain number of welds, after an intermediate annealing.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!